Vertical Comforter Quilting Machine

ABM Robo Quilter

Robo-Quilter Single Needle Quitling Machine

-

The world's first fully automatic vertical quilting machine.

-

The State of the art Robo Quilter uses only 1/6 of the floor space of a conventional panel quilter.

-

Expect to save 80% of floor space.

-

Reduce labor cost by 75%.

-

Increase production by 25%.

Features & Benefits

- The sewing head is a full computer controlled quilting system capable of sewing any pattern on your product.

- A color touch screen user interface with an advanced computer processor allows for user friendly operation.

- The automatic bobbin changer is complete with two quick-change carousels that hold up to 8 bobbins each. This enable the operator to run multiple machines with less down time wasted during bobbin changes.

Fully Automatic Comforter Loading

- The Robo Quilter is highly automated and the most user-friendly machine available on the market today.

- Designed with the operator’s ergonomic needs in mind, the operator simply attaches the leading edge of the quilt.

- The product automatically indexes into the sewing position.

- The product is measured, and the product gripper mechanisms adjust for seize changes automatically.

- The grippers then automatically grip and stretch the product, preparing it for quilting.

- Due to the machine’s extensive automation, depending upon the pattern, one operator can easily run multiple machines.

Sewhead Mechanics

- Many different sewheads are available.

- Sew speeds reach 4,500 SPM.

- Gantry transport speed reaches 1,000 IPM.

- Standard frame size 120” x 110.”

Completed comforter Load Sequence

- After the product is indexed into the sewing position, the quilt cycle can begin.

- The machine automatically backtacks at the start and finish of the pattern.

- Many different patterns are available – from simple continuous to complex tack and jump.

- When tack and jump is utilized, the Robo Quilter automatically backtacks and thread trims at every start and stop.

- After the sewing cycle, the product is automatically indexed and folded in half so the operator can remove it effortlessly.

Automatic Bobbin Changer

- Robo Quilter is the only machine available with a fully automatic bobbin changer.

- The machine keeps track of the number of products that can be sewn per bobbin.

- Every time a bobbin is fully utilized, the machine will automatically remove and discard the empty bobbin while inserting a new bobbin.

- The changer holds up to 8 bobbins.

- When the carousel is emptied, the operator can quickly and easily replace it with a full one.

Color Touch Screen Operator Interface

- The Robo Quilter is equipped with an extremely user-friendly color touch screen operator interface.

- The programming computer is a standard PC using a Windows 10 IoT embedded operating system.

- Standard CAD systems are available for pattern generation.

- A consistent stitch length is produced under all sewing conditions.

- Production data is available.

Precision Engineered

- ABM’s expert team of engineers has spent many hours designing and testing the mechanisms utilized on the Robo Quilter.

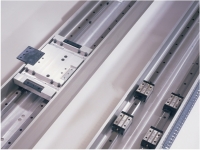

- The Robo’s gantry robot design utilizes precision-machined linear ball bearing guideways for all axis of motion.

- Due to rigorous stress analysis, we’ve created the most advanced and efficient system available today.

Quality

- ABM International, Inc is a vertically integrated manufacturer with in-house design, programming, welding/fabricating, machining and assembly.

- With over 70 years of experience in manufacturing quilting machines, our highly trained experts staff consistently delivers the quality our customers deserve.

In House Machine Design

- ABM’s highly trained engineering design team anxiously awaits your projects.

- We are available 24 hours a day for customer service, so you can rest well at night!

Technical Data

- Windows 10 Embedded IoT Pentium-based PC

- 128GB Hard Drive

- USB 3.0

- Max, material size 120” x 110”

- Max. sewing line 128” x 128”

- Max. axis speed 1,000 IPM

- Max. sewing speed 4,500 SPM

- Machine weight 10,500 lbs.

- 220 Volts Three phase, 20 amps

- 100 PSI at 2.5 CFM

- Floor space 5’ x 17’